In recent years, glass fibre reinforcement manufacturer HMP Group, whose products are recognized on the market under the brand name "REBARMAT", has made its mark on the European construction map as one of the most innovative companies in the sector. Its CEO Alise Novikova says the company’s focus is on the building materials of the future – products that outperform traditional materials in terms of both technology and environmental sustainability.

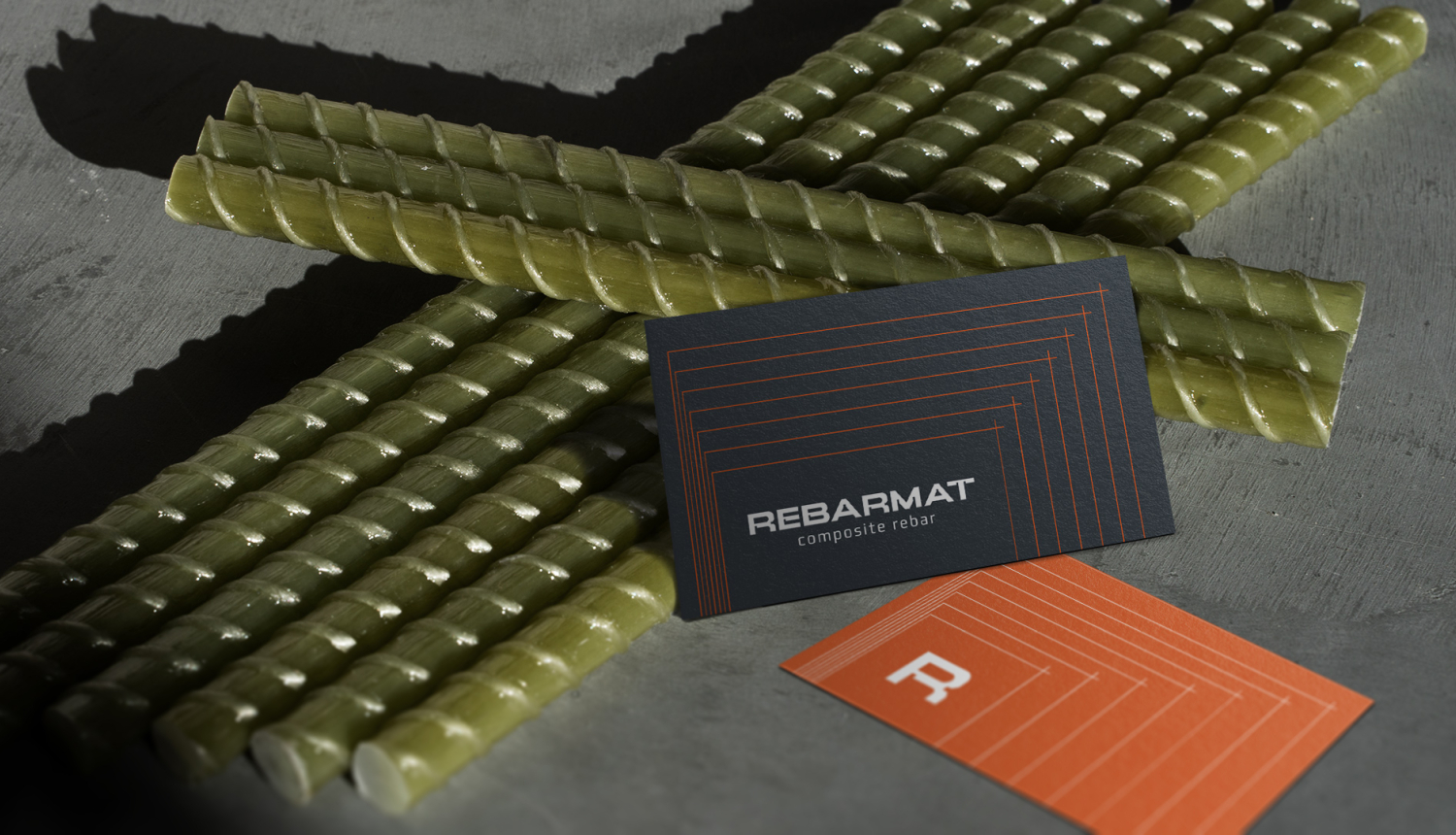

HMP Group specialises in the development of glass fibre reinforced polymer (GFRP) and mesh. This is a material that offers a significant alternative to steel as it is lighter, more resistant to corrosion and more climate friendly. This technology is increasingly in demand in construction throughout Europe, where sustainable solutions are becoming more the norm.

The company’s entire operation is concentrated in Adāži, Latvia, where more than 6.5 million metres of composite materials are produced annually in a 2000 square metre production facility. Volumes are growing and so are the team, expertise and technological capabilities. Close cooperation with the Investment and Development Agency of Latvia and European Union funding instruments has also been an important turning point in the company’s development, helping to strengthen export capacity and move forward with digitalisation.

“REBARMAT” brand products are already available in more than ten European countries, including Germany, Italy, Spain, Finland and Sweden. Demand is still on the rise and the company is confident about the future. It is of particular note when the company’s solutions are chosen by state and municipal authorities for infrastructure projects where not only quality, but also sustainability are essential. More European cities are thinking about climate neutrality, and HMP Group can offer exactly what is needed: lightweight, safe, durable and environmentally friendly materials.

The company sees its development and growth in innovation, and this innovation is purposefully permeating all areas of the company’s operations. HMP Group is constantly improving both the chemical composition of its materials and its production processes. The company is particularly proud of the fact that all production equipment is built in-house. “This gives us a huge advantage – we can control quality, innovate quickly and be technologically independent,” says Ms Novikova. This allows the company to react quickly to orders and offer solutions tailored to the specific project or climatic conditions.

The applications for GFRP materials are broad: from public transport stops and road infrastructure to tunnels, concrete elements and a variety of specialised construction projects. Ms Novikova explains that GFRP combines high durability, excellent corrosion resistance and remarkable lightness. In addition, the material conducts neither heat nor electricity, making it ideal for a variety of urban infrastructure applications.

HMP Group has a clear vision for the future – to become one of the leading GFRP manufacturers in Europe. The company is approaching this with a deliberate investment plan, increasing production volumes, introducing automation, developing intelligent systems and expanding export markets. Energy efficiency and digital transformation also feature prominently in the strategy, which goes hand in hand with the objectives of the European Green Deal.

In addition to its commercial activities, HMP Group is actively involved in various European Union climate programmes, becoming a partner in the common journey towards sustainable construction. “We don’t just produce a quality product, we want to be part of the solution,” Ms Novikova says. “We are working not only to build a competitive company, but also to lay the foundations for a sustainable future. Not only for ourselves, but also for our customers, for Latvia and possibly for the whole of Europe.”