Romāns Sidorovs,SIA „GroGlass” Member of the board

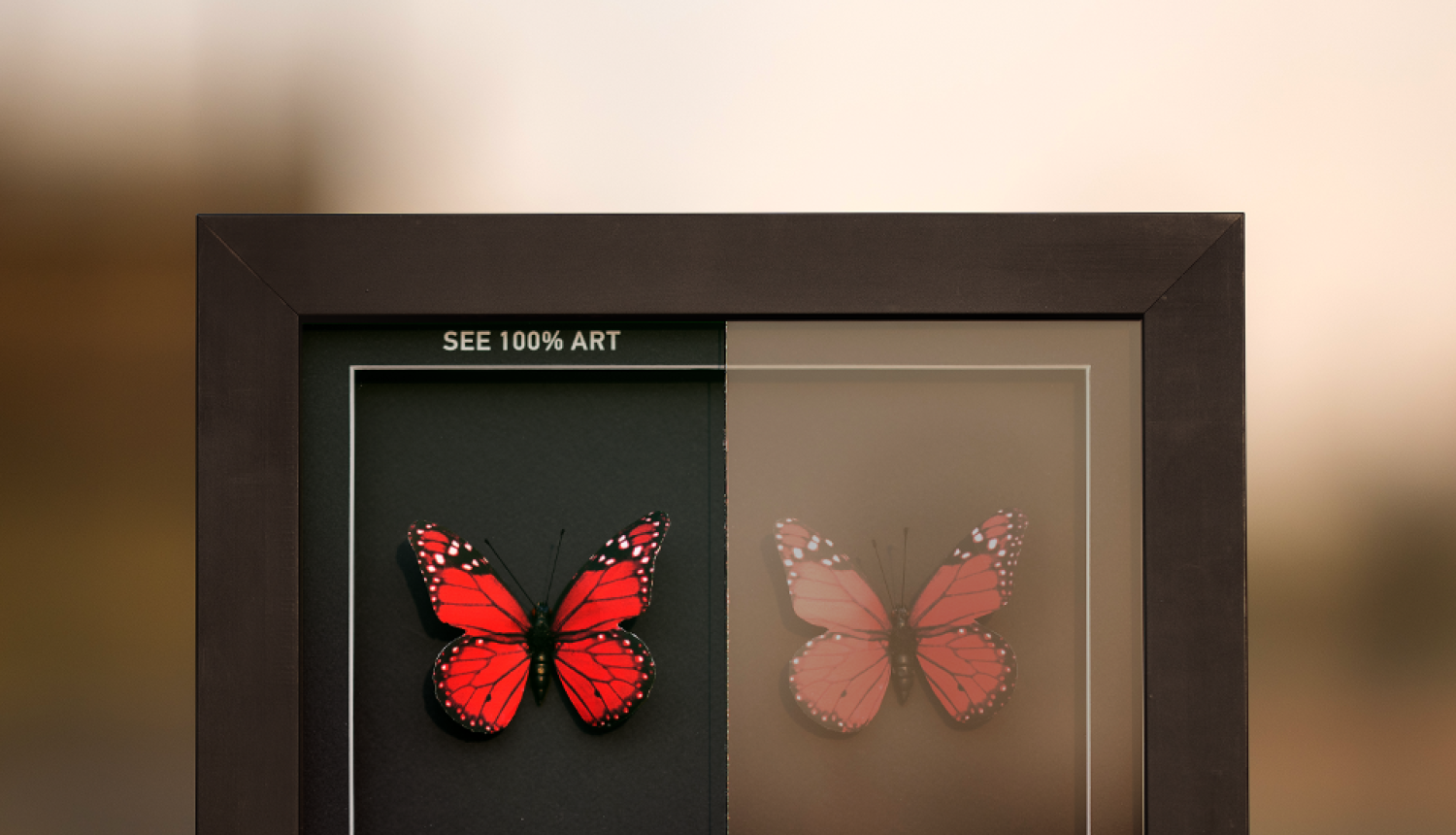

Groglass is one of the few companies in the world making glass with anti-reflective coating which is used for framing and preserving works of art, as well as for numerous other technical applications. The technology developed by the company can also ensure 99% UV protection and less than 1% light reflection, achieving exceptional picture clarity.

The beginnings of the nanotechnology company Groglass are connected with the Latvian research centre Sidrabe, which invented a vacuum spraying technology for glass. Sidrabe investors, which after the collapse of the Soviet Union began investing in various technology and science intensive companies, decided to develop and commercialise the promising technology. So Groglass was founded as a subsidiary company. “There is a piece of equipment from Sidrabe at our production facility with a ‘Made in Latvia’ label, and we are proud to be using this high-tech device made here in Latvia in our daily work”, said Romāns Sidorovs, Groglass Member of the Board.

Last year, Groglass’ turnover was EUR 23 million while operating profit exceeded EUR 8 million. “Every year, we grow by another 10 to 15%”, he said. The company has two production facilities in Rīga with about 200 employees.

Product development takes seven years

The main Groglass product is invisible glass. Unlike ordinary glass, this material has anti-reflective and UV-protection properties, which are important for framing shops, large art galleries and museums and other customers which use the company’s products for technical applications, such as electronic displays and refrigerated display cabinets.

“There is only one other company in the world that can make high-quality ‘invisible’ acryl. It took over seven years to develop this product. We faced many obstacles, but we believed in what we were doing, and together with our investor we managed to complete the development of the product”, said R. Sidorovs.

Groglass actively works with framing shops. The company also supplies glass to manufacturers of refrigerated display cabinets for food retailers. “We also make glass for electronic devices which can be used, for example, as information displays in airport and railway stations, advertising displays or museum displays”, explained R. Sidorovs.

Groglass mainly works with corporate customers, but recently the company has also turned to the consumer segment. He added that currently, this business brings only a small portion of the company’s turnover, but the company is looking into its options and is planning to expand its cooperation with consumers in the framing business in the future.

Exporting from day one

Since its first day in business, Groglass has been exporting almost all of its product range. “Since 2010, we have been exporting almost 100%”, said R. Sidorovs. The first country where the company sent its products for greenhouses was the Netherlands. In search of potential partners, the first customers who decided to give the Latvian-made solution a try came from the Netherlands. Since that time, the number of countries that the company exports to has reached 45. The largest export market is Europe followed by the US, China and Australia.

“Competition in the export market is fierce. We can continue working and growing because we have chosen our niche and focus, i.e. our invisible glass. It may not be a very large niche globally, but we are the best in the world in it and we can provide the best products and customer services. It enables us to keep our market share”, said R. Sidorovs.

The company may expand to multiple segments where competition is much stiffer, but there, the company is unlikely ever to reach this good a position even if investing heavily in marketing. That is why the company is focusing on its existing niche.

Commercially, Russia’s attack on Ukraine has not affected Groglass’ business, as the share of the Russian and Ukrainian markets in the total turnover was less than 0.5%. However, the war did affect electricity and gas prices. Glass is the main raw material used by the company and it’s made using gas, the price of which has skyrocketed. The company has also been affected by rising electricity prices. “However, we can adapt by increasing the efficiency of our production facilities and compensating at least some of the costs by raising prices. Our customers understand”, said R. Sidorovs.

Ability to adapt to changing conditions

Groglass’ DNA contains two crucial components, i.e. the ability to adapt and to adhere to proven values.

“We are a market leader in almost all of our segments, but at the same time we have competitors whose turnovers are in billions. Our turnover is about EUR 25 million, which in itself means that we have a better ability to adapt to changes. Without that we wouldn’t be able to export almost 100% of our products and remain in the market leader's position”, noted R. Sidorovs.

In addition to being flexible and able to adapt to circumstances, the company also sticks to proven values. Of course, if something does not work, Groglass’ team makes changes and looks for new methods. “If we believe that we can make a specific product, we are looking for ways to do it”, he said.

Plans for the third production facility are already underway

During its development, Groglass has used various state support instruments. The company follows what support programmes are available, mainly focusing on the support for participation in trade fairs, research projects, etc. The manufacturer also uses subsidies to cover research costs.

“We use the Competence Centre programmes, as our research costs reach several million euros every year. There are also our long-term projects: the development of a single product may take as long as seven years. These are huge investments, but they enable us to create unique products”, explained R. Sidorovs.

Groglass also relies on the state support of investments in technologies and equipment. For example, the company built its second production facility using the JRP project co-funding. “Now we are thinking about a third factory, which would require tens of millions of euros in investments. Currently, several support programmes are open, and we hope we’ll be able to receive state support for our new production facility”, said R. Sidorovs.

He positively views their cooperation with the Investments and Development Agency of Latvia (LIAA), Central Financial and Contract Agency and the Competence Centre. “We are happy that LIAA is on the side of businesses and listens to us both at the officials and the top management levels. I hope it continues in the future, because it is vital for helping other companies as well to reach their export goals”, said R. Sidorovs.